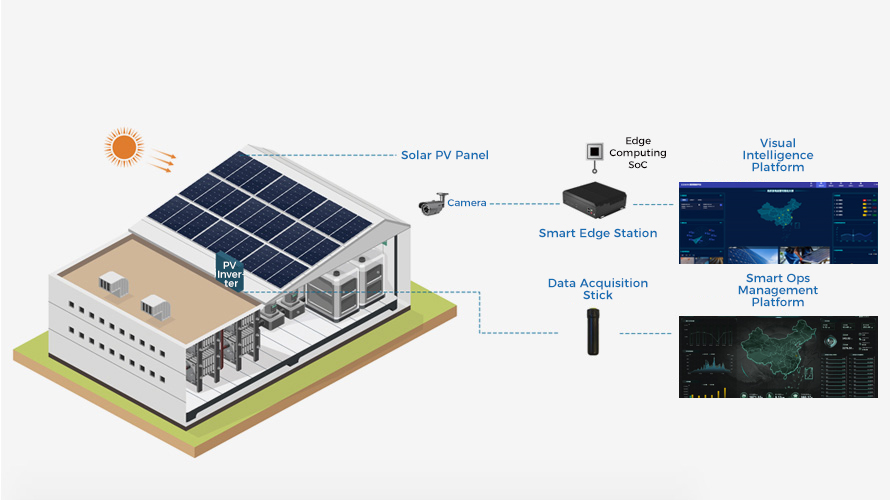

Leveraging cutting-edge technologies such as AI, IoT, and edge computing, ESWIN Computing’s smart energy solutions enable efficient data collection, local processing, and smart analysis of data from PV power stations. Through accurate data insights and smart decision-making support, they help enterprises make more efficient use of renewable energy, improve the operational efficiency, and implement smarter and greener energy management.

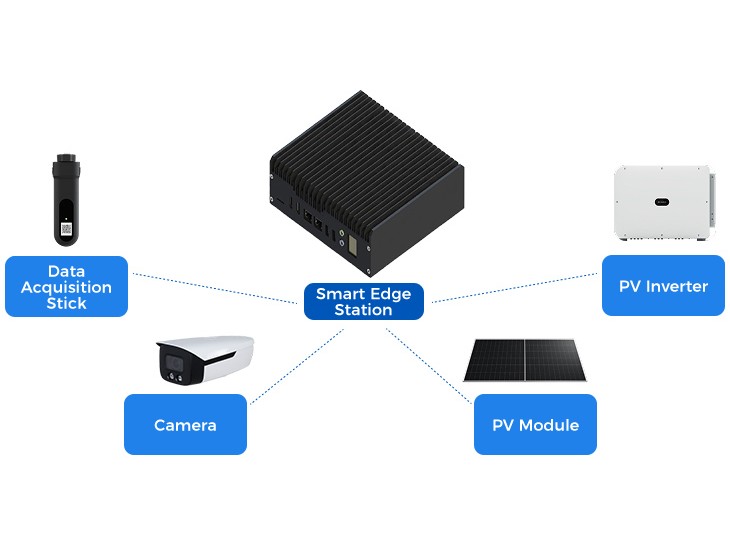

Smart edge devices designed for edge applications feature high processing power, flexible configurations, a wide operating temperature range, and high environmental adaptability, and support remote maintenance management. Based on the hardware platform, more than 100 self-developed algorithms are provided, making it possible to use algorithms to define hardware functions. Algorithm packages from different industries are available to create industry-specific smart edge analysis boxes. This product offering boasts high performance and is also cost-effective, making it a favored choice for edge AI computing.

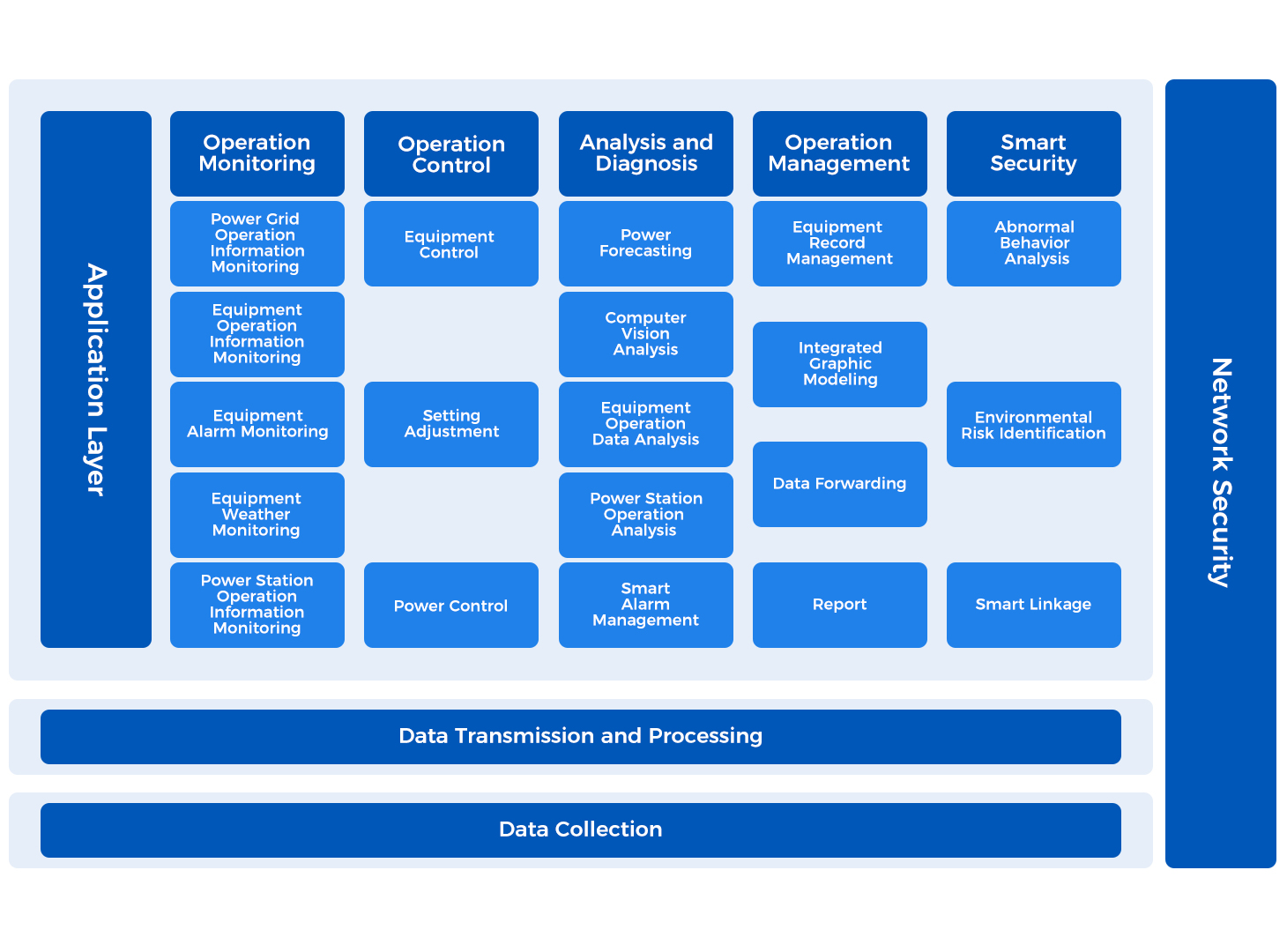

The smart operations management platform uses sensors and other smart devices to collect and analyze data from PV power stations in real-time, such as power generation levels, equipment temperatures, and light intensity. Advanced data analysis and AI technologies are used to conduct fault diagnosis, assess the performance, and provide optimization recommendations accordingly. The platform enables remote monitoring, intelligent alerting, and efficient operations, improving the power generation efficiency and operational stability of PV power stations.

Real-Time Aata Collection and Processing

Real-Time Aata Collection and Processing The self-developed RISC-V edge computing SoC EIC7700X offers processing power of up to 20TOPS at INT8 precision, meeting the requirements of live data collection, analysis, and processing.

Security Assurance and Privacy Protection

Security Assurance and Privacy Protection Data is processed locally at the edge, which effectively decreases the transmission of sensitive information and enhances data security and privacy protection.

Real-Time Fault Response

Real-Time Fault Response The system can promptly and accurately detect exceptions such as fire, smoke, and dangerous behaviors. Once any exception is detected, the alarming mechanism will be automatically triggered, ensuring safety in PV power stations.

High System Efficiency

High System Efficiency Data is transmitted in a structured manner, which significantly reduces the latency of data transmission to the cloud. This, therefore, improves the response speed and operating efficiency of the system.

Smart robots, drones, and high-precision sensors are used to monitor the operating data of energy equipment in real time, and detect potential hazards such as abnormal temperature and excessive vibration. Inspection reports are automatically generated, and 24/7 automated inspection is conducted to ensure the stable operations of equipment.

Based on high-resolution cameras and smart analysis algorithms, the solution monitors the operating state of equipment in real time and automatically detects equipment failures, violations by personnel, and fire hazards. Inspection routes are optimized based on big data analysis to improve the Ops efficiency and ensure the safe and stable operations of equipment.

Digital platforms and smart tools are used to carry out remote equipment monitoring and respond to faults promptly. Ops plans are optimize based on data analysis in order to reduce downtime, improve equipment uptime and Ops efficiency, and implement refined management throughout the lifecycle.

Sensors are integrated to build a comprehensive data collection network, and cutting-edge analysis technology is used to tap into the value of energy data. In-depth analysis of energy consumption patterns and equipment efficiency is carried out to improve the energy management, minimize waste, enhance the utilization efficiency, and provide data support for decision-making in businesses.

京公网安备 11030102011303号

京公网安备 11030102011303号