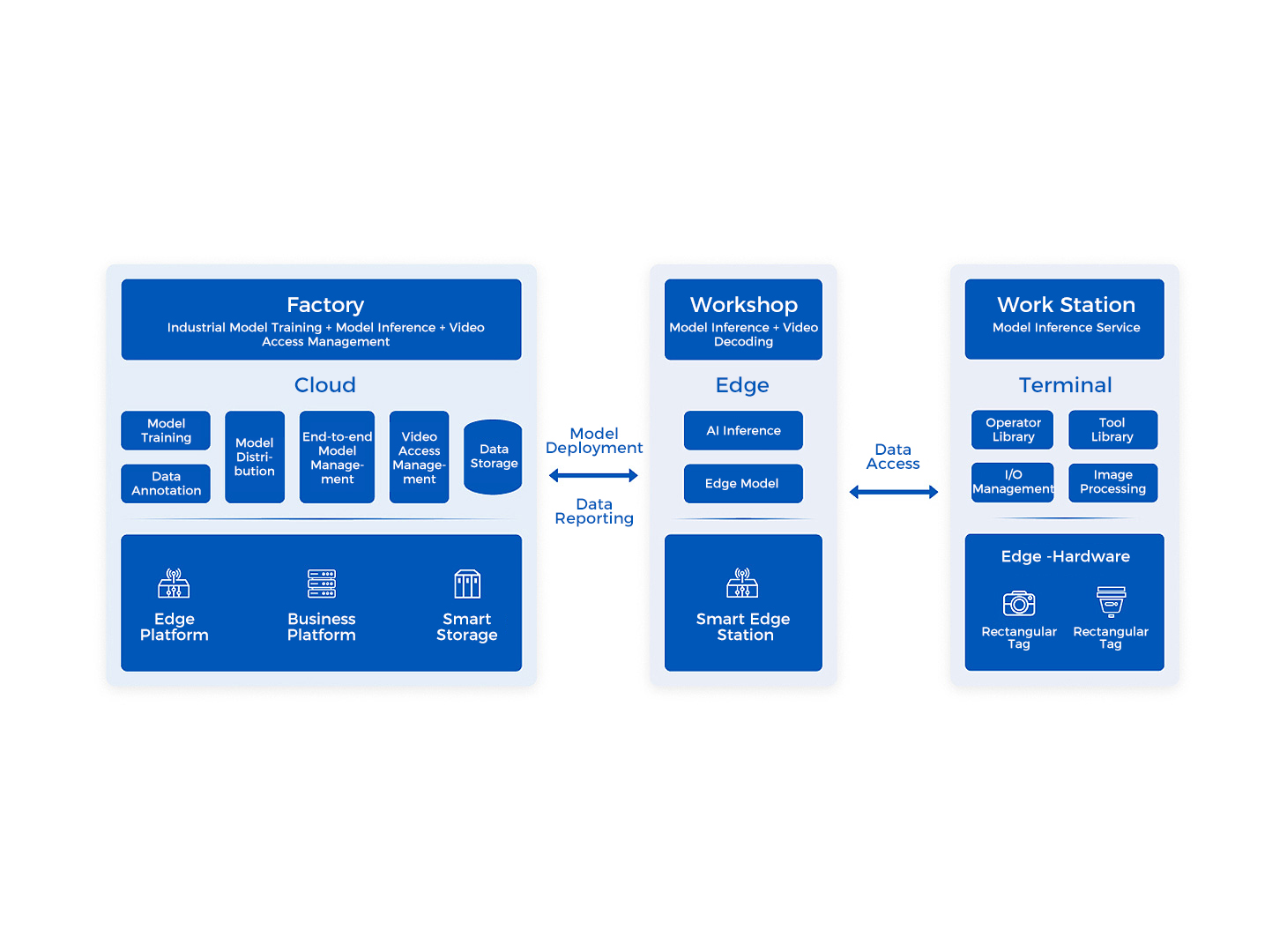

Amid the wave of digital transformation, smart manufacturing has played a vital role in promoting industrial upgrading and enhancing corporate competitiveness. ESWIN Computing’s smart manufacturing solutions feature the dual-drive model of “Real-Time Response at the Edge + Global Optimization in the Cloud,” aimed at helping the manufacturing sector embrace smart transformation and build efficient, flexible, and sustainable production models.

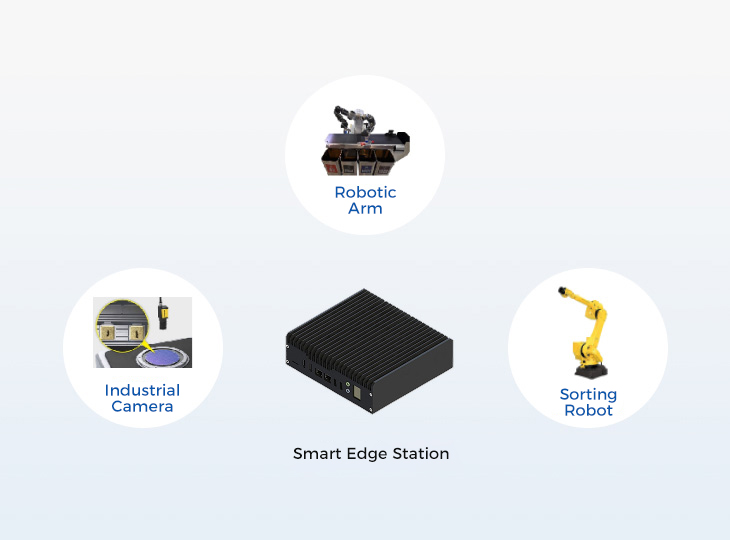

Smart AI devices designed for edge computing have high processing power and allow for flexible configuration. They feature industrial-grade design, are highly adaptable, and support remote Ops management. Following the concept of “algorithm-defined hardware,” they come with hundreds of built-in AI algorithms, which can be quickly deployed as an industry-specific smart edge station, making it a highly cost-effective smart edge solution.

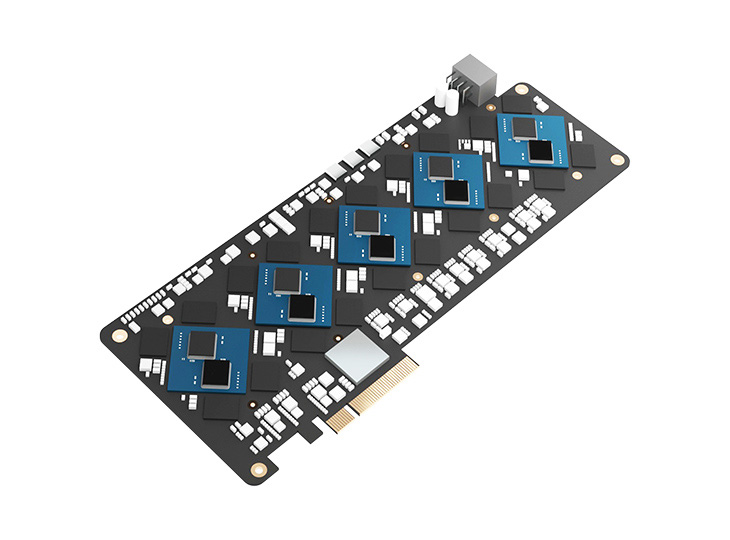

Dedicated hardware for smart computing acceleration integrate five RISC-V multi-purpose intelligent computing SoCs by ESWIN Computing, namely, the EIC7702X SoCs (each SoC contains 8 high-performance RISC-V core processors@1.8GHz). It boasts a robust 200TOPS of processing power at INT8 precision and has up to 320GB memory capacity, allowing high-precision LLMs to run more efficiently. It enables real-time video transcoding and compression and supports interconnection of up to 8 GPUs within a single server and server clustering for scalability to accelerate LLM inference for AI inference servers, video cloud platforms, and manufacturing management systems, fully meeting the demands for AI inference and hybrid computing acceleration.

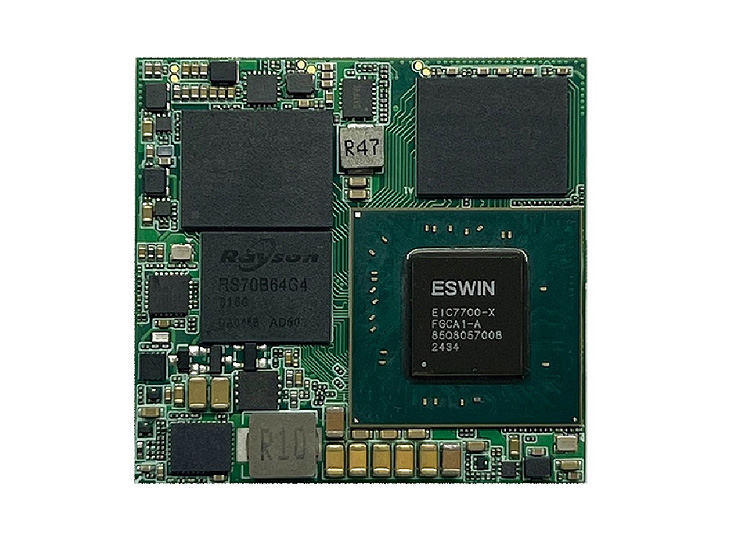

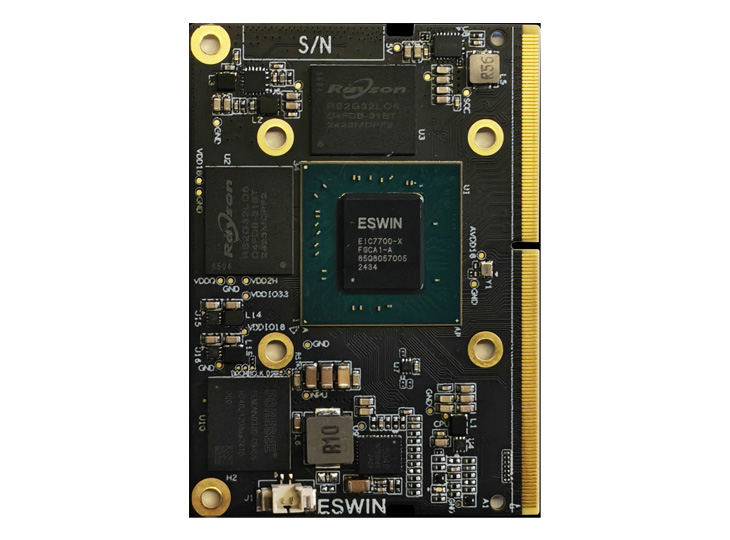

ESWIN Computing’s Open Standard Module (OSM) is an open standard-based, modular computing platform that complies with the dimension, interface, and power supply specifications of the industry. Featuring a standardized pin layout and stackable design, this module achieves cross-vendor compatibility and offers highly flexible, low-risk hardware development solutions for various fields such as smart video analysis devices, industrial AI PCs, embedded edge systems, smart manufacturing, and smart education.

ESWIN Computing’s System-on-Module (SOM) is an embedded core module which integrates edge computing SoCs, memory, storage, power management, PCIe, USB, Ethernet, and other peripheral interfaces into a single, compact design. Combining standardized interfaces and the custom carrier board, this module provides flexible and expandable embedded solutions that allow rapid deployment, making it suitable for a range of fields such as smart video analysis, embedded edge systems, smart manufacturing, and smart education.

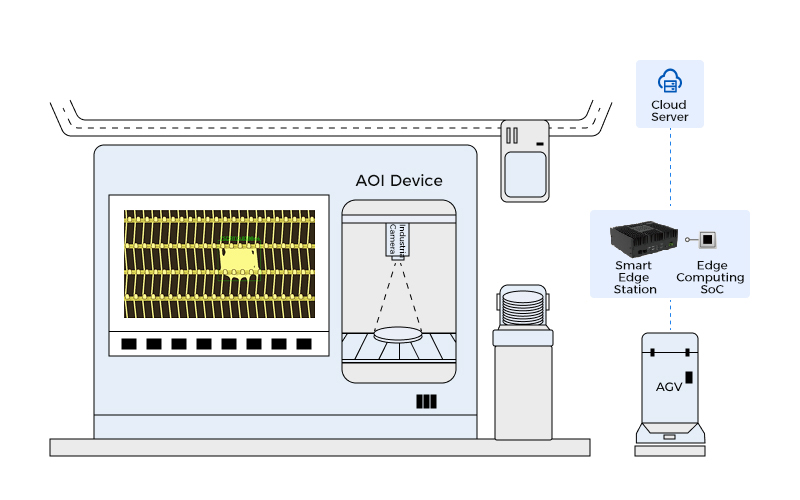

The industrial vision inspection system uses industrial cameras and smart sensors, coupled with advanced image processing algorithms, to automatically detect surface defects and dimensional deviations in products and facilitate efficient and accurate quality inspection, significantly improving the production efficiency and product quality.

Real-Time Response at the Edge

Real-Time Response at the Edge Comes with the EIC7700X, ESWIN Computing’s self-developed RISC-V edge computing SoC, to provide 20TOPS of processing power at INT8 precision, significantly increasing the speed of industrial vision algorithms to meet the demand for real-time response in edge computing.

Low Power Design

Low Power Design Improves energy efficiency while ensuring high performance, meeting stringent energy efficiency requirements of industrial applications.

High Flexibility and Extensibility

High Flexibility and Extensibility Supports flexible configuration and virtualization of computing power, is compatible with a variety of AI frameworks and programming interfaces, and can quickly adapt to different industrial applications and be extended as needed.

Leverages high-precision industrial cameras and smart image recognition algorithms to quickly and accurately detect minor defects (e.g., scratches, cracks, and dents) on the surface of products. The efficiency is several times that of manual detection, and the detection accuracy reaches the micron level, which significantly reduces the defect rate and guarantees product quality.

Relying on the monitoring network built upon the smart edge station, the system integrates cameras and sensors to monitor the production site in real time. The system intelligently detects nonstandard operations, intrusions in high-risk areas, and equipment abnormalities, and gives real-time alarms to prevent safety accidents and ensure personnel safety and the stability of equipment operations.

Employs computer vision and deep learning technology to conduct real-time analysis of personnel compliance and human-machine collaboration efficiency. The system intelligently detects abnormal behaviors and gives risk warnings, and continuously optimizes the operating mode, improving the production efficiency and making safety management smarter.

Through the smart interaction platform, robots perform high-precision, repetitive tasks, while people are responsible for complex decision-making and flexible operations, fully exploiting the advantages of each other. The system enables efficient human-machine collaboration to improve production efficiency and product quality while ensuring production safety.

京公网安备 11030102011303号

京公网安备 11030102011303号